Products

FUEL & LUBE SERVICE TRUCK 45 KL

Lube Fuel Service Truck, is a supporting unit for the maintenance process of heavy equipment at locations, plantations, forestry, etc. This unit is designed in an integrated manner with several dispensing modules at once, namely: Lube oil, water, grease, water, & waste oil which uses a pneumatic system with The Atlas Copco Diesel Engine Compressor is also equipped with a Fuel Module with a Hydraulic system from the PTO Transmission for Truck cars. This unit is very efficient and effective in its operation and is used with various models of Trucks, SCANIA, HINO, NISAN, VOLVO, MAN, IVECO etc. Cargo Trucks

Key Features and Components

Lube Tank System:

Capacity: 45.000 liters divided into multiple compartments for different types of lubricants (e.g., engine oil, hydraulic oil, grease, coolant).

Material: Tanks are typically made from stainless steel or high-density polyethylene (HDPE) to prevent corrosion and contamination.

Design: Internal baffles to minimize fluid movement during transport.

LUBE SERVICE CONTAINER

A lube service container is a specialized portable unit designed for the storage, transportation, and dispensing of lubricants. These containers are essential for maintaining machinery and equipment in industries such as construction, mining, agriculture, and heavy equipment maintenance. They ensure that lubricants are readily available on-site, promoting efficient and timely maintenance operations.

Key Features and Components

Container Structure:

Material: Typically constructed from high-strength steel or aluminum for durability.

Design: Modular and portable, often resembling a shipping container for easy transport and deployment.

Capacity: Varies depending on requirements, but can include multiple compartments for different types of lubricants and fluids.

FUEL TRUCK 32 KL

A fuel truck with a 32 KL (32,000 liters) capacity is designed for the safe transport and dispensing of fuel. These trucks are widely used in various industries including transportation, construction, mining, agriculture, and emergency services, providing a mobile fuel supply for machinery, vehicles, and equipment.

Key Features and Components

Fuel Tank:

Capacity: 32,000 liters.

Material: Typically made from high-strength steel or aluminum, with internal coatings to resist corrosion and ensure fuel quality.

Design: Often cylindrical with internal baffles to minimize fuel sloshing during transport.

FUEL TRAILER 65 KL

A fuel trailer with a 65 KL (65,000 liters) capacity is a large, mobile unit designed for the safe transport and dispensing of fuel. These trailers are typically used in industries such as mining, construction, agriculture, and emergency services where large volumes of fuel need to be transported to remote locations or directly to equipment and vehicles in the field.

Key Features and Components

Fuel Tank:

Capacity: 65,000 liters.

Material: Usually constructed from high-strength steel or aluminum, often with internal coatings to resist corrosion and ensure fuel quality.

Design: Cylindrical or rectangular design with internal baffles to prevent fuel sloshing during transport.

Chassis and Frame:

Construction: Heavy-duty steel frame designed to support the weight of the fuel tank and ensure structural integrity.

Axles and Suspension: Multiple axles and robust suspension systems to handle the weight and provide stability during transportation.

FUEL SKID 50 KL

Temporary storage place for Fuel A fuel skid with a 50 KL (50,000 liters) capacity is a modular and portable fuel storage system designed for safe and efficient storage and dispensing of fuel. These units are commonly used in remote locations, construction sites, mining operations, and industrial facilities where a permanent fuel storage solution is not feasible.

Key Features and Components

Fuel Tank:

Capacity: 50,000 liters.

Material: Typically made from steel or aluminum, often double-walled for added safety and leak prevention.

Coatings: Internal and external coatings to protect against corrosion and ensure compatibility with different types of fuel (e.g., diesel, gasoline, jet fuel).

Baffles: Internal baffles to reduce fuel movement and maintain stability during transportation.

SPRAYING WATER TRUCK 80 KL

A spraying water truck with an 80 KL (80,000 liters) capacity is a large vehicle used for various applications, such as dust suppression, irrigation, and firefighting. Here are the key features and components typically found in an 80 KL spraying water truck:

Key Features and Components

Water Tank:

Capacity: 80,000 liters.

Material: Often made from steel, aluminum, or high-density polyethylene (HDPE) to withstand the weight and pressure of the water.

Baffles: Internal baffles to prevent water from sloshing and maintain vehicle stability.

CRANE SERVICE TRUK

A crane service truck is a versatile vehicle equipped with a crane, designed to perform lifting and material handling tasks in various industries, including construction, mining, utilities, and transportation. These trucks are essential for lifting heavy equipment, materials, and machinery, providing mobility and flexibility for on-site operations.

Key Features and Components

Crane:

Type: Can be a telescopic boom, knuckle boom (articulating), or stiff boom crane, depending on the specific requirements.

Capacity: Varies widely, typically ranging from a few tons to over 50 tons.

Reach: The crane’s horizontal and vertical reach, often adjustable with extensions or additional sections.

Rotation: Full 360-degree rotation capability for maximum flexibility.

WASH DOWN WATER TRUCK 20 KL

A wash down water truck with a 20 KL (20,000 liters) capacity is designed for the high-pressure cleaning of equipment, vehicles, and surfaces. These trucks are essential in industries like mining, construction, and agriculture, where keeping machinery and work areas clean is crucial for safety and efficiency.

Key Features and Components

Water Tank:

Capacity: 20,000 liters.

Material: Usually constructed from high-strength steel or aluminum to withstand the pressure and weight of the water.

Design: Equipped with internal baffles to prevent water sloshing during transport and ensure stability.

Pump System:

BOTTOM DUMP TRAILER

A bottom dump trailer, also known as a belly dump trailer, is designed for transporting and unloading bulk materials such as sand, gravel, asphalt, and other aggregates. Unlike traditional dump trailers that unload materials by tilting, bottom dump trailers release their loads through gates located on the underside of the trailer. This design allows for more precise and controlled unloading, making them ideal for applications such as road construction, mining, and large-scale material transport.

Key Features and Components

Trailer Structure:

Material: Constructed from high-strength steel or aluminum for durability and to handle heavy loads.

Design: Typically includes a V-shaped or semi-cylindrical body to facilitate smooth material flow during unloading.

Capacity: Varies based on size and design, typically ranging from 20 to 40 cubic yards.

Hopper and Gates:

Hopper: The bottom of the trailer where materials are stored. Designed to funnel materials towards the gates for unloading.

Gates: Located at the bottom of the hopper, these gates open to allow materials to flow out. They can be operated hydraulically or pneumatically.

Control System: Gates can be controlled from the cab of the truck, allowing for precise control over the unloading process.

SIDE DUMP TRAILER 12 - 80 CM

A side dump trailer is a type of dump truck used to transport loose material like sand, gravel, or demolition waste. Here are some key features and benefits of side dump trailers:

Features:

Side Dumping Mechanism:

Unlike traditional end dump trailers, side dump trailers tilt to the side to unload their contents. This makes them suitable for dumping in tight spaces or where overhead clearance is an issue.

Capacity:

They come in various sizes and capacities, often ranging from 20 to 40 cubic yards, depending on the model and manufacturer.

Construction:

Built with durable materials like high-strength steel to withstand heavy loads and harsh working conditions.

LOW BED TRAILER 60 TON

A low bed trailer, also known as a lowboy or low-loader trailer, is designed for transporting heavy, oversized loads that other trailers cannot accommodate due to height restrictions. A 60-ton low bed trailer specifically refers to one with a capacity to carry loads up to 60 tons. Here are some key features, benefits, and typical uses of a 60-ton low bed trailer:

Features:

Low Deck Height:

The deck is much lower than that of standard trailers, which allows for the transport of tall equipment and machinery while remaining within legal height limits.

DUMP TRUCK

A body dump truck, commonly referred to as a dump truck or tipper truck, features a large open-box bed that can be tilted to unload its contents. These trucks are essential in construction, mining, and various industrial applications for transporting and dumping materials like sand, gravel, demolition waste, and more.

Key Features of a Body Dump Truck

Chassis and Frame:

The chassis is the main structure to which all other components are attached.

It must be sturdy to support the heavy loads and the stress of dumping operations.

Dump Body:

The dump body is the cargo area of the truck.

Made from durable materials like steel or aluminum to withstand heavy and abrasive loads.

Can vary in size and shape depending on the specific application (e.g., rectangular for construction, V-shaped for mining).

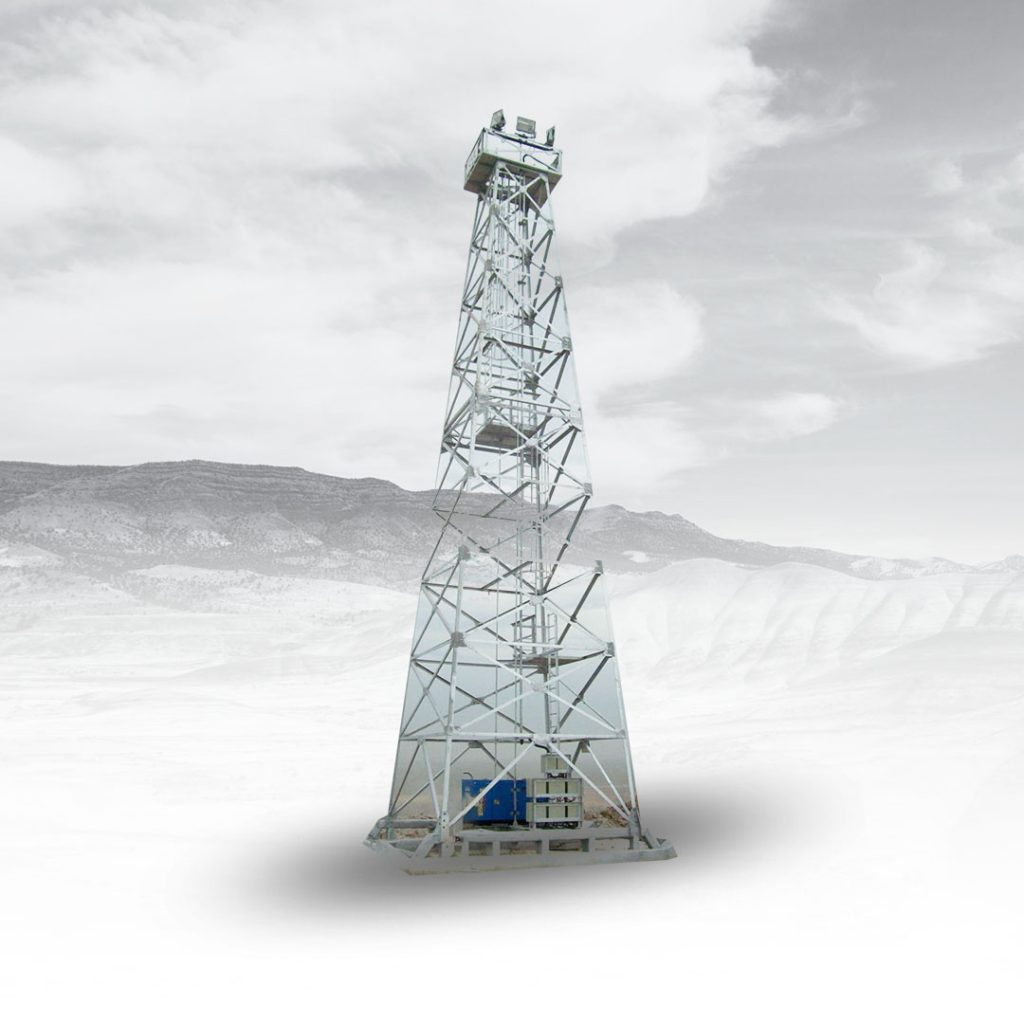

SKID TOWER LAMP

A skid tower lamp typically refers to a portable lighting tower mounted on a skid base, commonly used in construction, events, and emergency situations where temporary but powerful illumination is needed. These towers are designed to be easily transportable and provide adequate lighting in outdoor or large indoor spaces.

Key Features of a Skid Tower Lamp

Skid Base:

Mounted on a sturdy skid or trailer base for easy mobility.

Can be towed behind a vehicle or moved using equipment like forklifts.

Lighting Fixtures:

Typically equipped with multiple high-intensity lamps mounted on extendable masts.

Uses metal halide, LED, or other high-efficiency lighting technologies.

Height and Coverage:

Masts can extend to significant heights (up to 30 meters or more) to illuminate large areas effectively.

Provide 360-degree lighting coverage.

DEWATERING PUMP

MBS Pumps, from water supply pumps, dewatering pumps to centrifugal water pumps in both horizontal and vertical pump configurations. MBS Pumps offers high-quality mining pumps from multiple manufacturers to fit almost any mining application.